Disclaimer – We at Evolve are manufacturers of premium interior products that are crafted using new-age building materials like liquid metal and decorative concrete. Please visit our products page to learn more about our offerings and services. We are also on the look out for channel partners to help increase our presence. Visit our partner page to know more about the partnership opportunities.

When it comes to upgrading your concrete surfaces, you may find yourself torn between three options: decorative concrete coatings, concrete paint, and lime plaster. All three options can transform your space, but which one would be the better choice for you? The answer lies in the battle between aesthetics and durability. While decorative concrete coatings offer a durable range of textures, colors, and patterns to enhance the look of your surfaces, concrete paint provides a low cost solution for a quick and easy makeover, and lime plaster brings a touch of elegance and tradition with its smooth and timeless finish.

So, which one should you choose? It ultimately depends on your requirements. Let’s dive deeper into the differences between the three materials to help you make an informed decision.

What Are Concrete Finishes?

Concrete finishes, as a whole, are specially composed concrete treatments that help one achieve an aesthetic, textured concrete surface. Apart from being known for their decorative look, these finishes also stand out as:

- A durable surface treatment

- A breathable layer on the walls, ceilings or floors

- An elastomeric choice of finish

Why Are Concrete Finishes Trending Now?

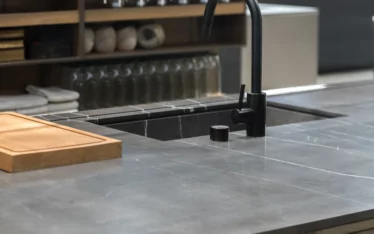

Textured concrete finishes have witnessed a remarkable rise in popularity, making their presence felt in design magazines, social media platforms, and even high-end showrooms. So, what are the reasons behind this trend? First and foremost, concrete finishes offer a unique and contemporary aesthetic that is hard to replicate with other materials. The smooth, clean lines and minimalist appeal of textured concrete finishes make them a perfect fit for modern and industrial-inspired interiors.

Additionally, concrete finishes are highly versatile, allowing homeowners and designers to experiment with various textures and finishes. From polished concrete floors that exude elegance to textured concrete walls that add depth and character, the possibilities are endless. The ability to customize concrete finishes according to individual preferences and design concepts is a major draw for many.

Another reason behind the popularity of concrete texture finishes is their durability. Unlike other materials that may show signs of wear and tear over time, concrete finishes are known for their resilience. They can withstand heavy footfall, resist scratches and stains, and are not easily affected by moisture or temperature changes. Thus making them an ideal choice for high-traffic areas such as kitchens, bathrooms, and entryways.

Types of Concrete Surface Finishes

1. Decorative Concrete Coating:

Decorative concrete coating is manufactured by combining concrete with other binding materials. This material allows a designer to achieve a 2 mm thin layer of actual concrete on any surface. These coatings are generally manufactured in an aqueous base, which makes them environment-friendly. Depending on the formulation, many decorative concrete coatings are texturable owing to their fluidity, thus allowing any trained applicator to craft beautiful concrete textured surfaces.

Advantages:

- Texturability: Unlike regular or casted concrete, decorative concrete coatings allow us to craft a wide variety of unique and artistic textures on any base substrate like wood, MDF, as well as retrofit tiles, veneers, and laminates. With certain formulations, you can even polish decorative concrete to a marble-like smoothness and consistency to achieve a natural gloss like sheen. The look and feel that you will achieve in using decorative concrete will be like real concrete, not flat like regular painted surfaces.

- Long Lasting: Since it is entirely composed of concrete, it has the inherent strength and durability of concrete.

- Stone-like hardness: Just like concrete, this finish, when cured, will harden over time and reach its peak strength after 21 days of curing to achieve stone-like hardness.

- Ease of application: The finish can be applied with the help of a spray gun, trowel, roller, or brush to achieve handcrafted concrete textures and seamless surfaces.

- Versatility: Decorative concrete coatings can be applied on both interior and exterior surfaces. You can also use it to coat furniture, patios, or art pieces to achieve a contemporary look across all your surfaces. No matter what the base substrate is – plastered wall, wood, tiles, or any other surface – the final look of your concrete texture will be the same.

- Breathability: Decorative concrete coatings are breathable in nature, which also lends the material its elastomeric property, i.e., it can absorb cracks up to 0.5 mm.

- Multiple color options: You can also stain decorative concrete to achieve a textured surface in a color of your choice, thus breaking you free from the same old gray shades.

Limitations:

- Higher pocket pinch: The quality, functionality, and versatility of the material make it a high-end product. This product is best for consumers who want the feel and depth of real concrete and prefer a natural material over pigmented paints.

- Longer application time: Unlike paints, the application of decorative concrete coatings requires multiple application steps and a longer drying process, thus requiring longer application time than paint.

- Skilled application: Decorative concrete coatings are not DIY-friendly. It can be used to create textured surfaces only by professionals like texture painters and general contractors who have proper knowledge and prior experience of wall texturing.

2. Concrete Paint:

Concrete texture paints mimic the look and feel of concrete but are not entirely composed of real concrete. They are made up of pigments that are mixed in either solvent or water-based solutions and are a quick fix for people looking to achieve a concrete look and feel for their surfaces without burning a hole in their pockets.

Advantages:

- Short Application Time: Concrete paint can instantly give the appearance of a concrete looking surface due to its short application time. If you are working on a retrofit or refurbishing project and are on a super tight timeline, concrete paint would be a good bet.

- User-friendly: Concrete paint is relatively easy to apply and does not require specialized equipment or extensive preparation. With proper surface cleaning and some basic tools, like brushes or rollers, you can apply it without significant difficulty, making it a DIY product.

- Budget Friendly: Compared to other concrete finishing options, concrete paint is the most budget friendly option owing to its DIY nature and mass availability. It provides a low cost way to enhance your surfaces without the need for an onsite application team.

- Multiple color options: : Concrete paint is available in a wide range of colors and finishes, offering versatility in design. You can choose from solid colors, patterns, or even create decorative effects like faux finishes or stencils, allowing you to achieve different aesthetics based on the requirements of your projects.

- Quick availability: Concrete paints, just like other paints, are mass produced and easily available in the market, unlike decorative concrete coatings that are manufactured in time for your project needs.

Limitations:

- Performance: Since these are not real concrete finishes, they do not have the inherent performance of concrete. Thus, concrete paints can be limiting in the types of textures you can create.

- Durability issues: Concrete paint may not be as durable as other concrete finishing options. Over time, exposure to different weather conditions can cause the paint to chip, peel, fade, or wear away, requiring periodic touch-ups or recoating.

- Limited application: Concrete paint is primarily suitable for indoor use or areas with minimal exposure to harsh weather conditions or heavy moisture.

- High maintenance: Concrete paint requires periodic maintenance to preserve its appearance and protective properties. Depending on the wear and tear, you may need to touch up or recoat the surface every few years. This can involve additional time and effort.

3. Lime Plaster:

Lime plaster is a traditional building material that has been used for centuries in construction. It is made by combining lime, sand, and water to create a plaster mixture. Lime plaster is easy on the eye and offers several unique characteristics and benefits, making it a popular choice for both interior and exterior applications.

Advantages:

- Breathability: Lime plaster is highly breathable, allowing moisture to evaporate from the walls, thus promoting a healthier indoor environment.

- Durability: Lime plaster has proven to be a durable material, with some historic lime plasters still intact after centuries. It can withstand weathering and is less prone to cracking or crumbling over time, making it a long-lasting choice for interior and exterior applications.

- Recyclable: Lime plaster is 100% eco-friendly. It is also recyclable and biodegradable, contributing to sustainability and reducing environmental impacts.

- Aesthetic appeal: Lime plaster provides a unique, soft, and natural appearance that is highly valued for its aesthetic appeal. It has a subtle texture and a matte finish that add character and warmth to walls. It can be tinted or pigmented, allowing for a wide range of color options.

Limitations:

- Longer curing time: Lime plaster requires a longer curing time compared to decorative concrete or concrete paint. It typically takes several weeks to fully cure and harden before it can be painted or decorated. This extended drying time can delay the completion of a project.

- Higher cost: Lime plaster is generally more expensive than decorative concrete or concrete paint. The cost is influenced by factors such as the quality of lime, application techniques, and skilled labor requirements.

- Limited availability: Locating suppliers or experienced craftsmen who specialize in lime plastering can be a challenge in some regions, resulting in additional logistical considerations.

- Maintenance: While lime plaster is durable, it may require periodic maintenance and upkeep. Over time, small cracks or imperfections may develop, and the plaster may need to be repaired or re-coated. Regular inspections and maintenance are necessary to ensure its long-term performance.

- Limited Texture Ability: While lime plaster allows you to achieve a textured look for your surfaces, the variety of designs you can create are limited.

The Comparison: Material Scoreboard

Concrete finishes stand out with distinctive features of their own and strike a comparison that is seen as a subjective debate among industry experts. Here’s a scoreboard rating the materials out of five to help simplify your decision-making process; 1 being the lowest and 5 being the highest.

| Quality | Decorative Concrete | Concrete Paint | Lime Plaster |

| Cost | 4 | 2 | 5 |

| Ease of application | 3 | 2 | 4 |

| Aesthetics | 5 | 2 | 5 |

| Versatility | 5 | 1 | 3 |

| Durability | 5 | 2 | 4 |

Conclusion: Which is better for your project?

When it comes to choosing between decorative concrete coatings, concrete paint, and lime plaster, there is no one-size-fits-all answer. It ultimately depends on your priorities and the specific needs of your project. If aesthetics are your top concern and you have room in your budget, decorative concrete coatings or lime plaster are your best bet. They offer a range of customization options and are more durable than concrete paint. However, if cost is a concern and you’re looking for a quick and easy solution, concrete paint may be the way to go. Whatever option you choose, make sure to consider the long-term maintenance and upkeep to ensure your surfaces stay looking great for years to come.

Note: We at Evolve manufacture exquisite surfaces in the form of wall panels and door skins which can be supplied to projects globally. We are based out of Mumbai, India. And have catered to projects nationally as well as internationally including Dubai, Kuwait, Bahrain, Riyadh, Italy, Kuala Lumpur, and Malaysia. Our specialty is working with new-age building materials like liquid metal, decorative textured concrete, and paintable corten steel.

We work with architects, interior designers, fit-out contractors, furniture manufacturers, and new homeowners. And are always on the lookout to collaborate with potential stockists and retailers worldwide.

If you are looking to source unique surfaces for your interior design projects fill out the form below to receive our e-catalog.